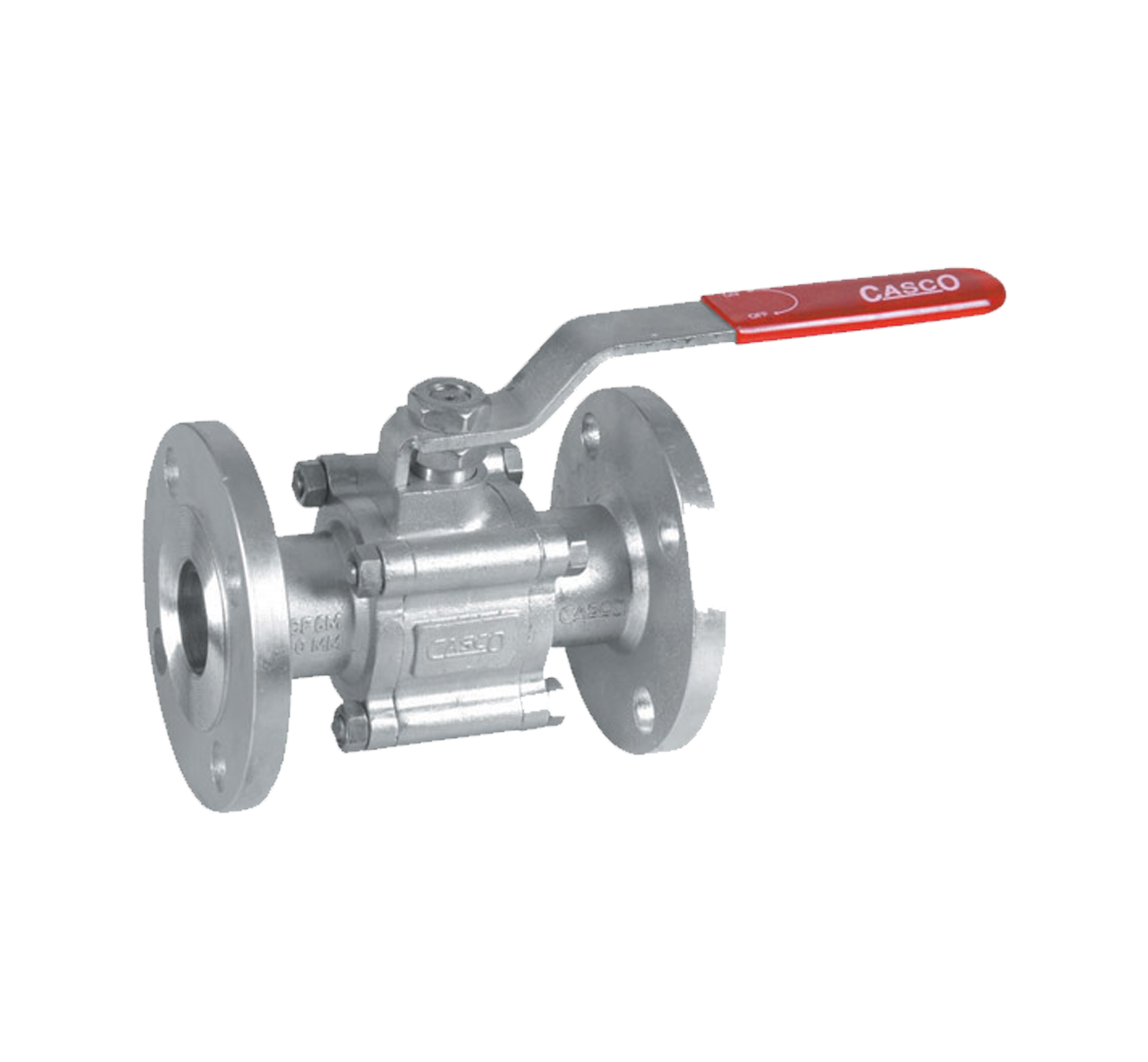

Ball Valves

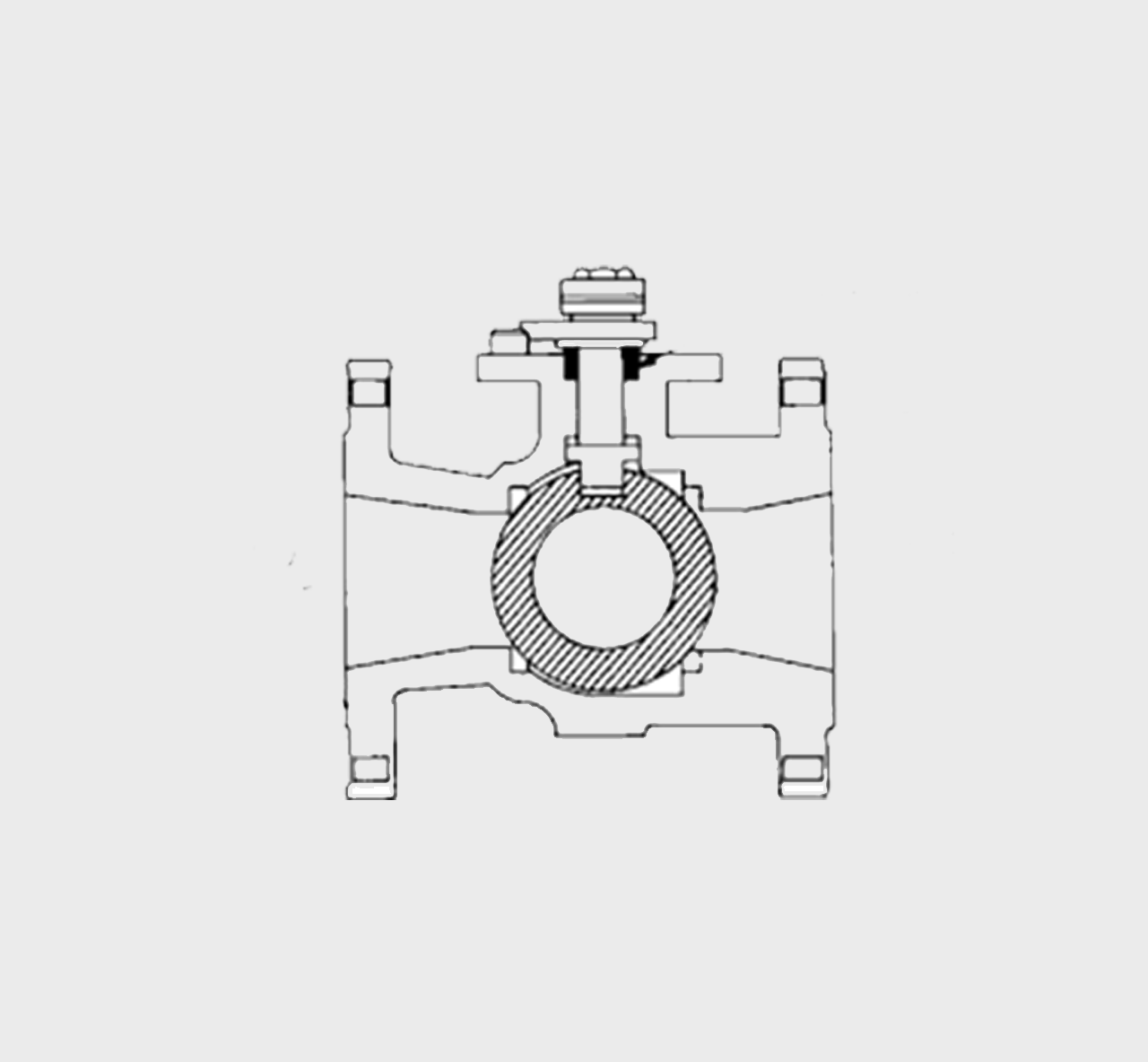

A ball valve has a quarter turn spindle connected to a ball inside the valve. The ball has a hole, or port, through the middle so that when the port is in line with both ends of the valve, flow will occur. When the valve is closed, the hole is perpendicular to the ends of the valve, and flow is blocked. The handle position lets you see the valve's position. On a floating ball type, the upstream pressure presses the ball against the seat, giving a tight shut off. On a trunnion mounted type, the ball is fixed; seat sealing action is achieved by the thrust of springs acting on the seat rings, as the pressure increases the fluid pressure pushes the seat rings against the ball.

Features & Benefits :

- All ball valve spindles are assembled from inside the valve to prevent blow out but in additionally, two Viton stem seals are used in conjunction with a PTFE packing gland to give triple sealed blow out proof stem protection.

- The two-piece body has a double connection seal for added security as a sealant is applied to the precision metal-to-metal seal between the body and the end piece.

- Interchangeable accessories and fittings such as the steel or aluminium levers and spindle extensions have been designed so that they can be substituted as required.

Applications :

- Ball Valves are used for flow and pressure control and shut off for corrosive fluids, slurries, normal liquid and gases.

- They are used in the oil and natural gas industry, but also find a place in many manufacturing sectors, chemical storage, and even residential uses.

- Air, gaseous, and liquid applications requiring bubble-tight service

- Instrument root valves

- Cooling water and feed water systems